eMaint

Maintenance and reliability teams, from single-plant industrial facilities to global, Fortune 500 companies, trust eMaint to plan, track, and streamline their maintenance programs. eMaint serves more than 50,000 users worldwide.

Take the helm of a digital command center for maintenance planning. Manage assets, schedule work orders, gather condition monitoring data with IoT technology, and much more.

Simplify Maintenance Management with eMaint CMMS

eMaint unites your team in the battle to enhance equipment lifespan and make maintenance profitable. With eMaint's leading multi-site and multi-language capabilities, your organization can standardize maintenance work across countries and languages. Using our sophisticated smartphone app, you can also arm your team in the field to create, action on, and close out work orders – even when they're offline.

eMaint users see a quick return on investment. Maintenance planning requires less labor and overall equipment uptime is enhanced. Looking to the future, eMaint is also an ideal partner for the era of predictive maintenance: you can see machine failures coming and work on the right asset at the right time.

Learn more about eMaint CMMS.

Configurable

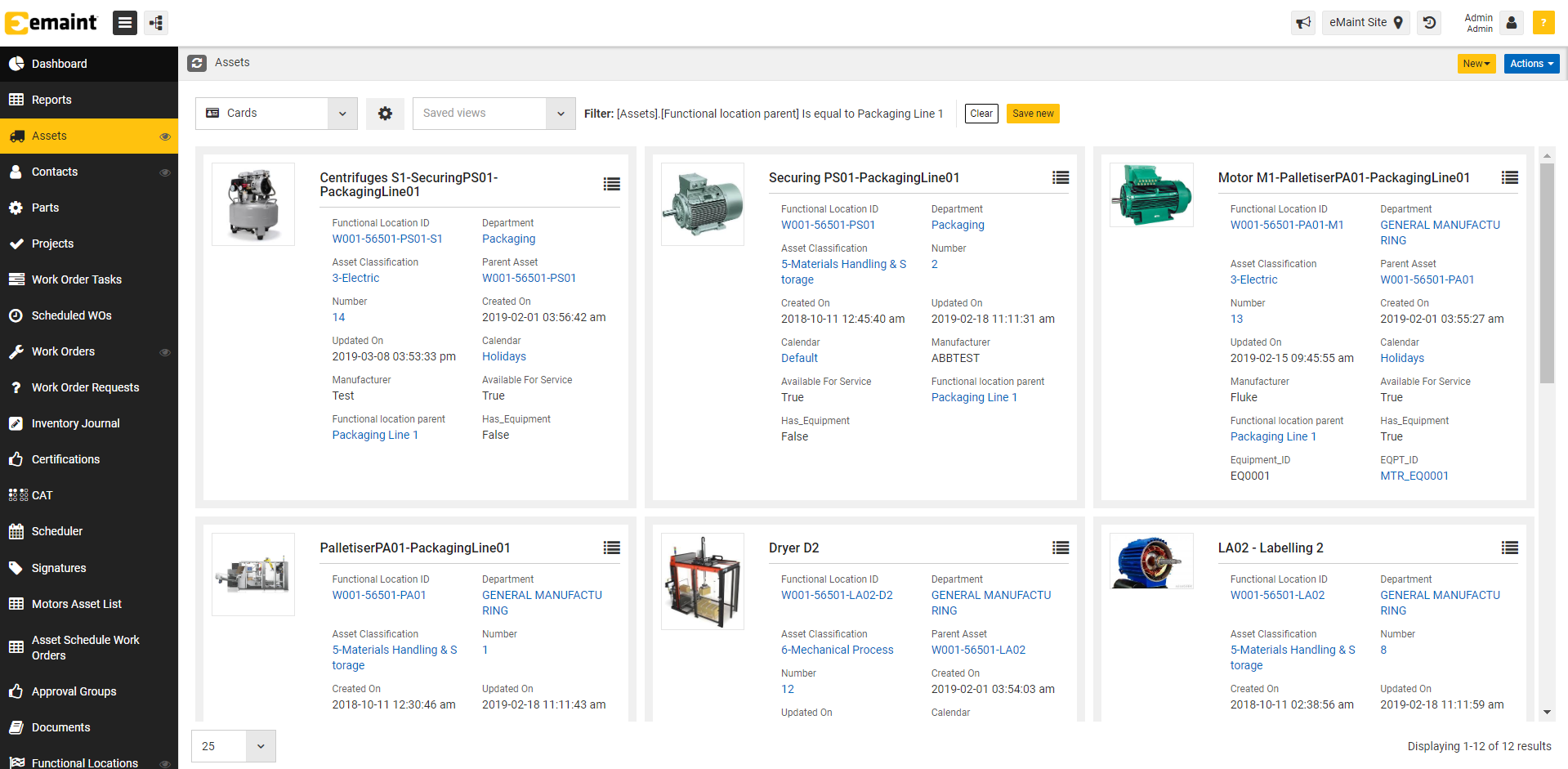

Work the way you want to work—without being limited by your maintenance management system. Within eMaint, you can tailor your dashboards, workflows, filters, and more to fit your industry and your needs.

Scalable

eMaint’s CMMS software adapts to fit your organization’s changing needs. You can even start with a small pilot program, prove the concept and get buy-in, and then roll it out to other teams, departments, and locations.

Flexible

eMaint offers a wide range of subscription packages designed to fit any budget and to help your maintenance and reliability goals. Our training options—online, at our office, or at your location—are equally flexible.

Using a CMMS increases your efficiency and productivity in a number of ways.

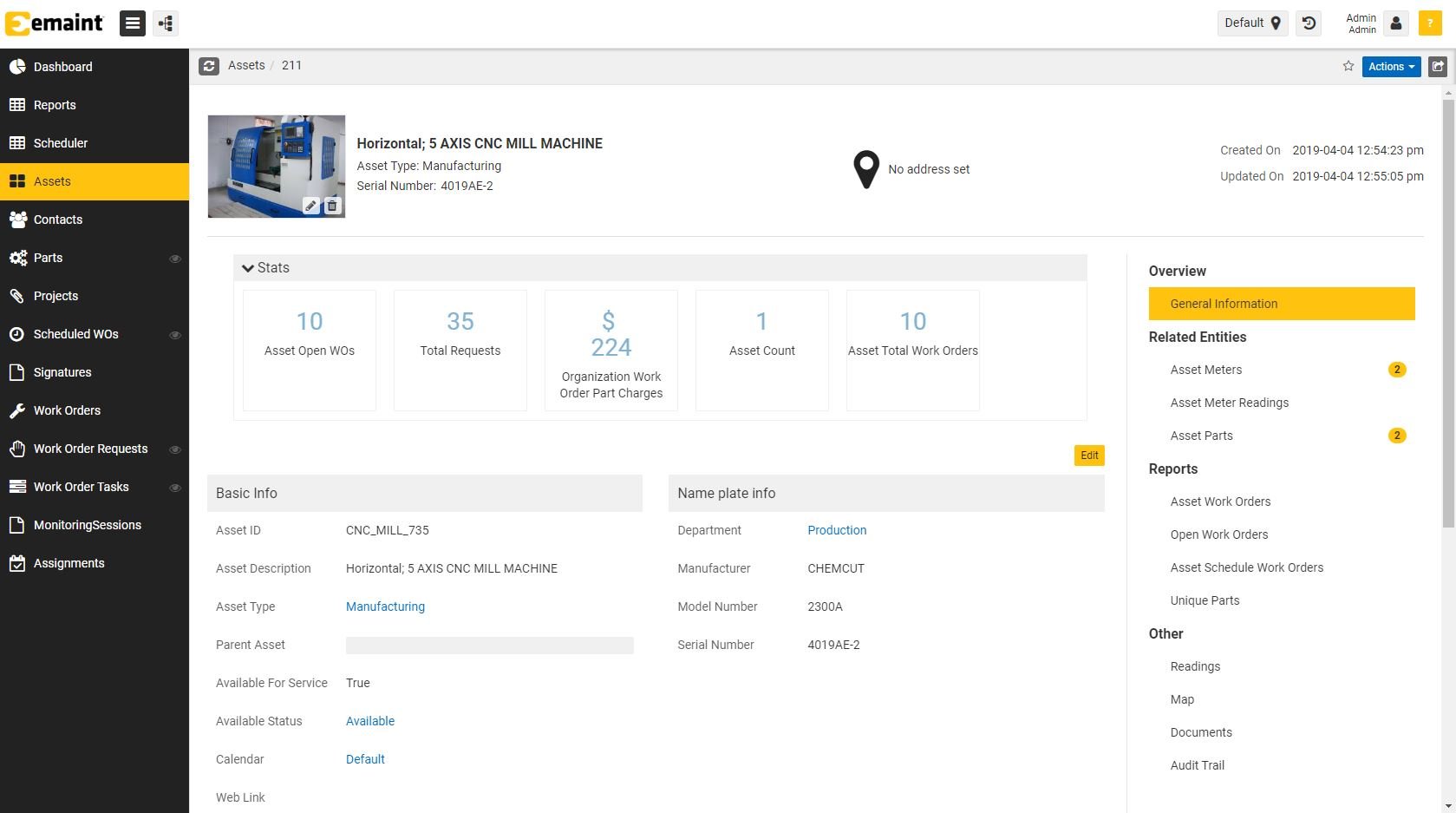

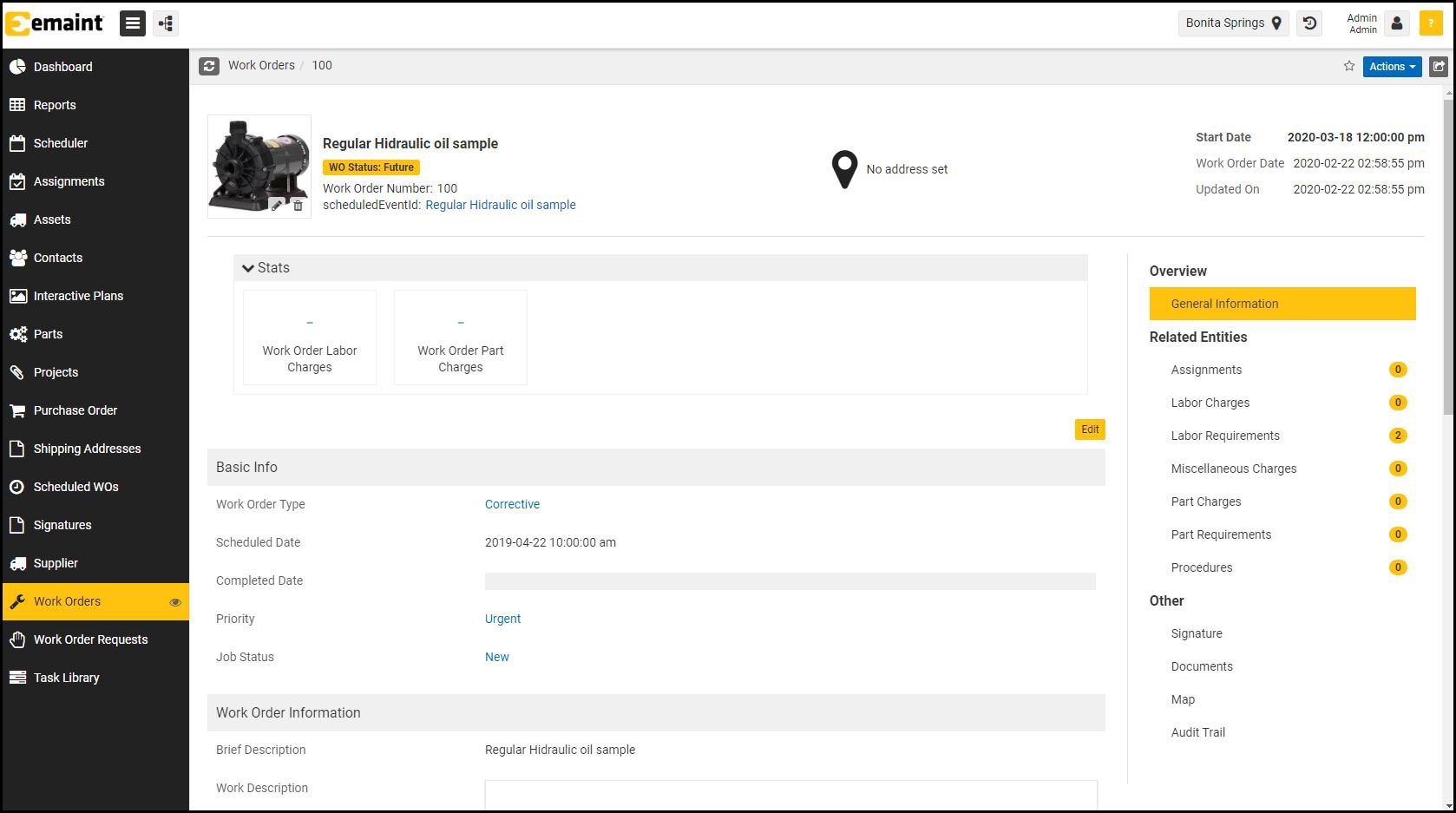

When everything from asset data to work orders to inventory management is integrated and made easily visible, transparency and accountability increase—along with work completion rates.

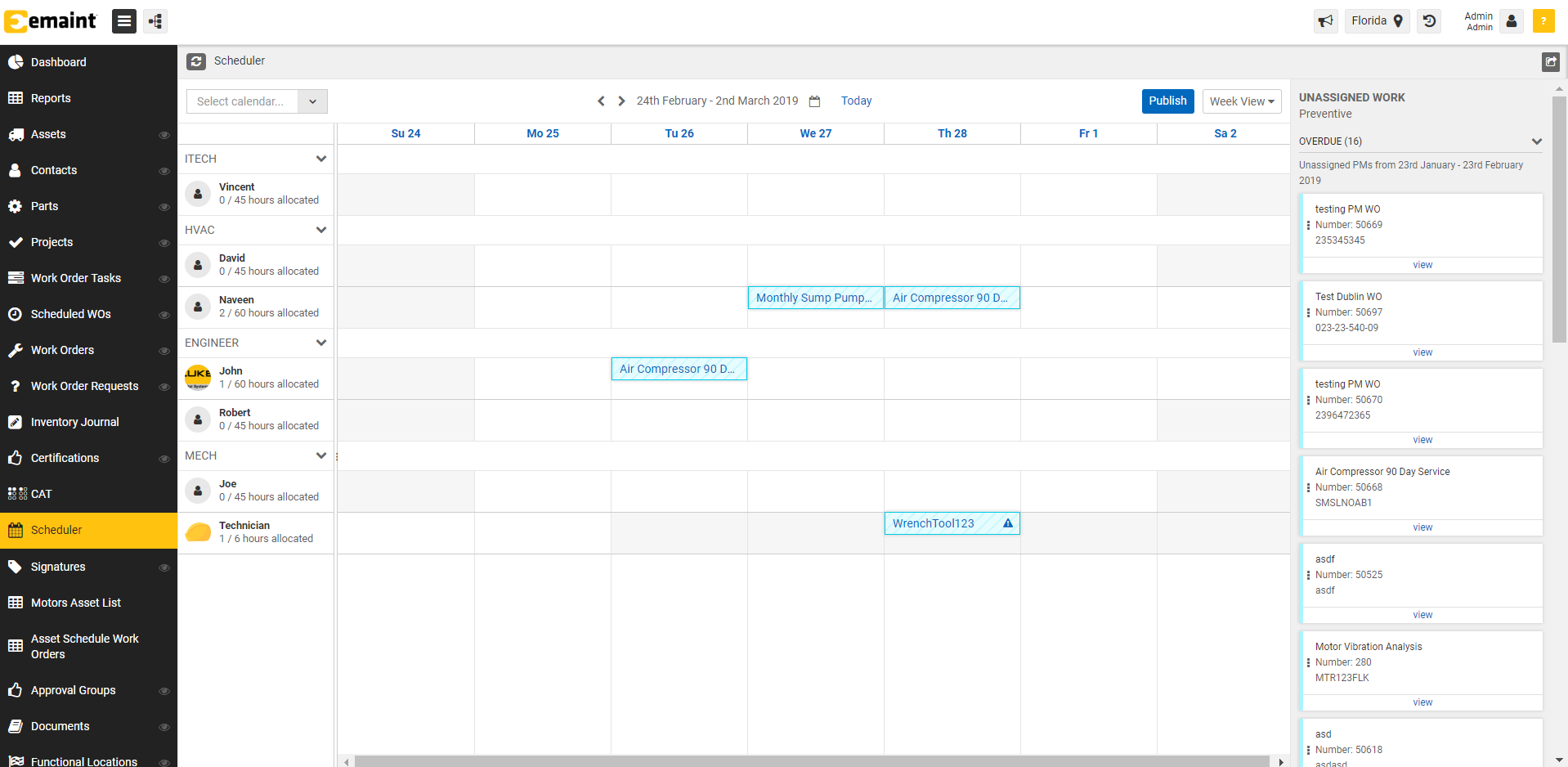

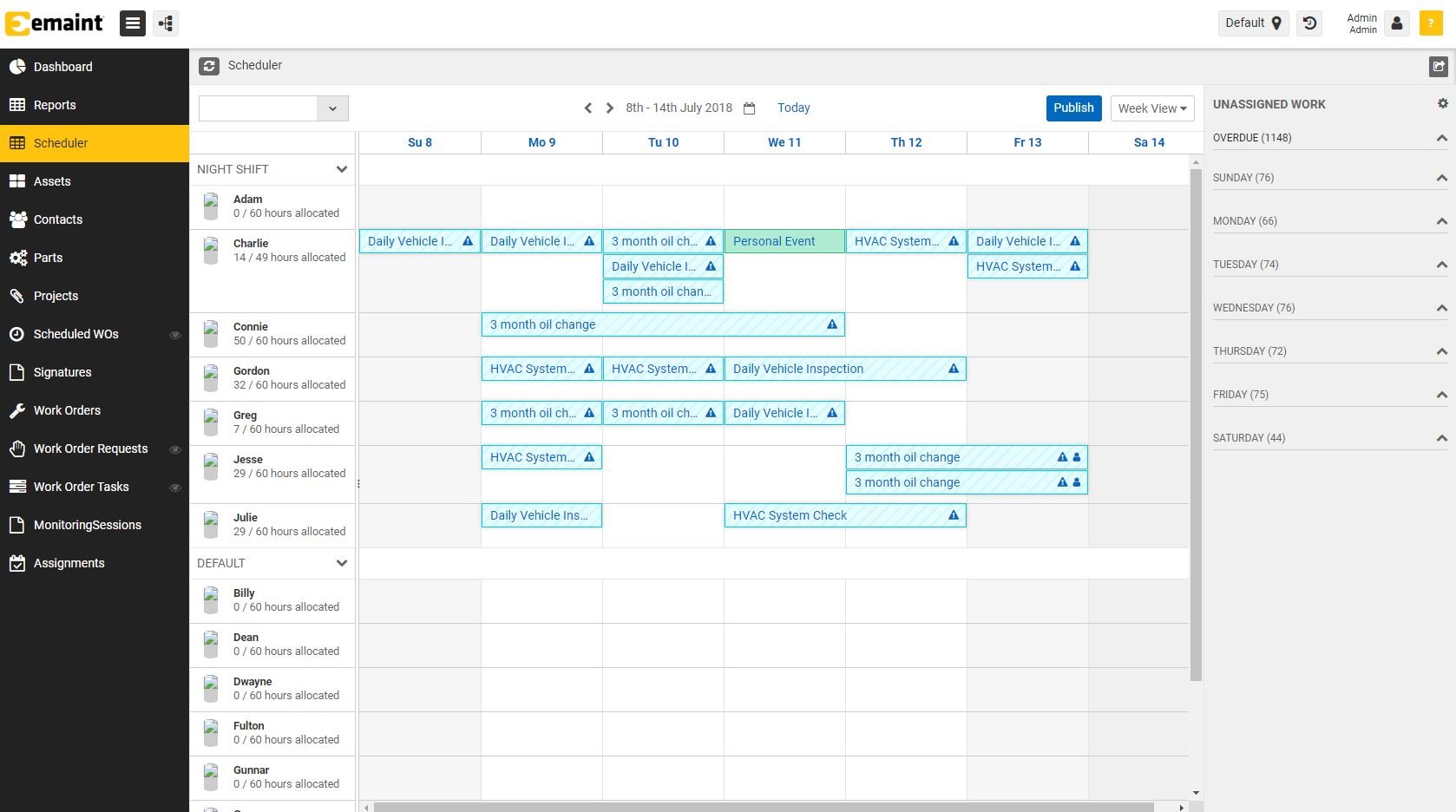

Labor resource allocation is improved through planning, scheduling, and tracking capabilities. And less time spent on manual data entry and unnecessary maintenance tasks means errors and wasted time are reduced and critical work is done first.

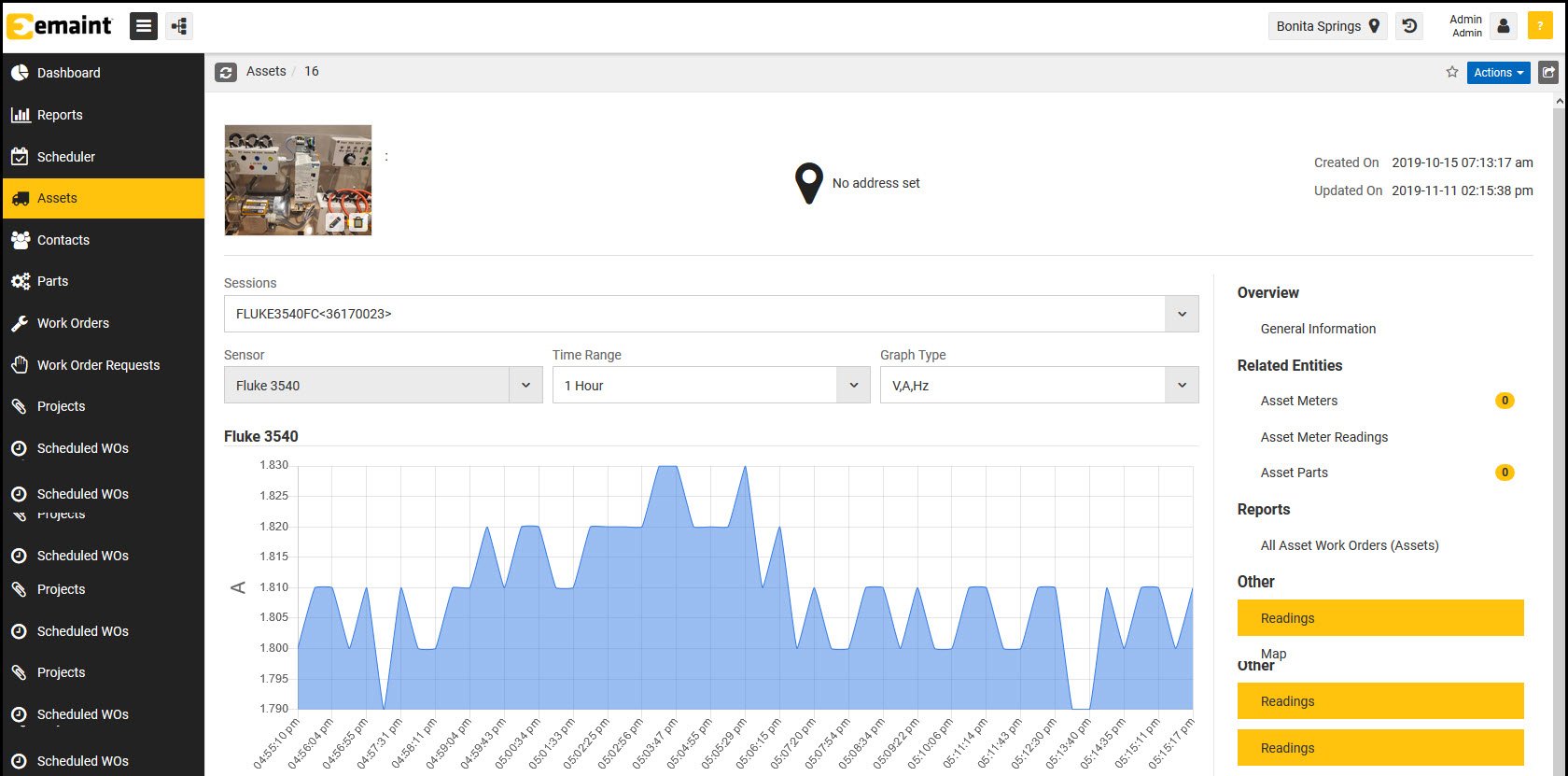

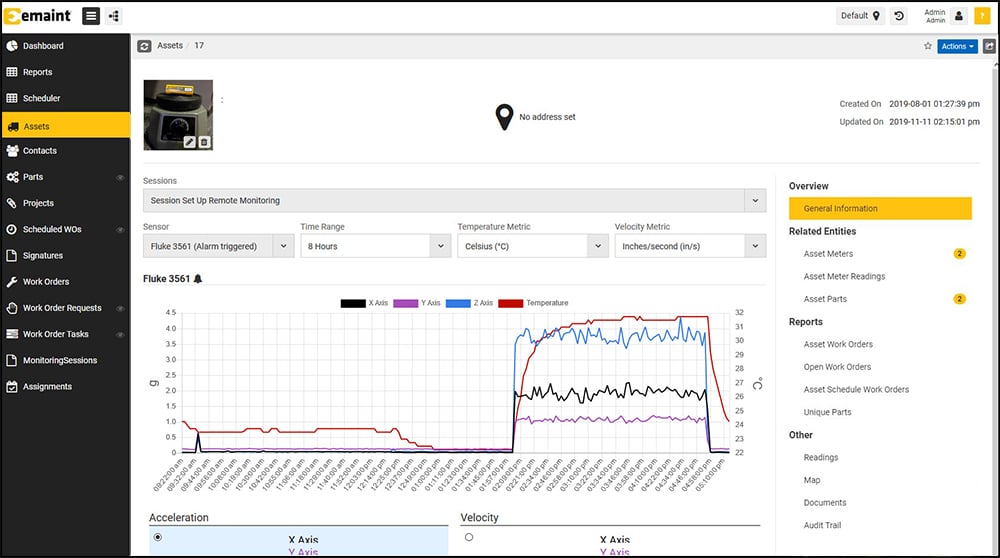

Maintenance team members can quickly and easily track performance and trends at the asset level, so potential failures are identified early.

Work orders can be automatically generated whenever an asset operates outside of the predefined boundaries of your choice.